Engineering

Extensive experience and high knowledge of our team in the electrical machines industry.

CONSULTING SERVICE

- . Analysis and calculations for new developments.

- . Advice on the design and assembly of test benches, as well as training for their use.

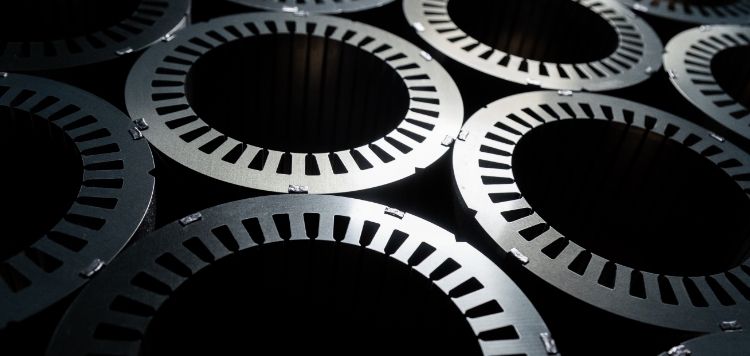

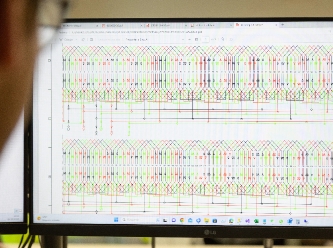

CALCULATION AND DESIGN OF ELECTRIC MACHINES

Ad-Hoc solutions:

The most advanced technology is materialized in intelligent software that allows us to carry out and ensure a more reliable and efficient analysis for each new design.. Throughout the entire product design phase, the customer actively participates with the ENERKOI team.

We assume all responsibility in terms of project leadership for the design and the development of the part engineering for correct industrialization.

RETROFIT

- . Diagnosis of electromagnetic behaviours of motors.

- . Motor performance improvements.

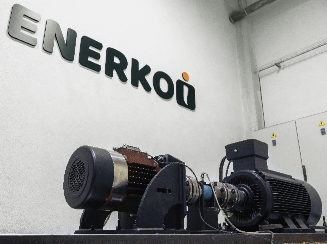

Tests

In ENERKOI we have our own fully equipped test bench where we make all the tests to check the correct operation of all our products.

TESTING FACILITIES:

- . Up to 250 kW.

- . Torque up to 5.000 Nm.

- . Speeds up to 5.000 rpm-s.

- . Custom tools for flanges and special shafts.

- . Simulation of different types of charge.

TYPE OF TESTS:

- . Winding resistance measurement,

- . Winding insulation resistance measurement.

- . Polarization index.

- . Dielectric strength.

- . Sense of rotation and phase sequence.

- . No load test.

- . Locked Rotor test.

- . Load and Overloard test.

- . Overspeed test.

- . Temperature rise test.

- . Vibration test.

- . Torque-Speed curves.

MOTOR CERTIFICATION:

- . We make all the required tests according to the standards of the corresponding Testing, Inspection and Certification company.

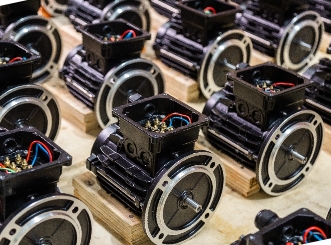

Product Industrialization

In ENERKOI, the entire production chain is subject to rigorous comprehensive control.

- . Industrialization of parts and processes of electric machines.

- . Industrialization of the customer’s electric machines.

We have 2 production areas located in Spain and Asia, which allows us to choose the best option according to the needs.

- . In Spain, in addition to the headquarters in Gipuzkoa for engineering, R&D, quality, and general logistics services, there is a production plant for high value-added products.

- . In Asia, we have located the production units for long-series and industrialized products. We have our personnel at origin to control production, as well as the verification of the final product.